3D printing technologies are not limited to producing plastic parts. Metal laser sintering (DMLS), one of the few 3D printing technologies that can produce parts directly from metal, was designed based on SLS technology. It is used for both rapid prototyping and mass production of metal parts.

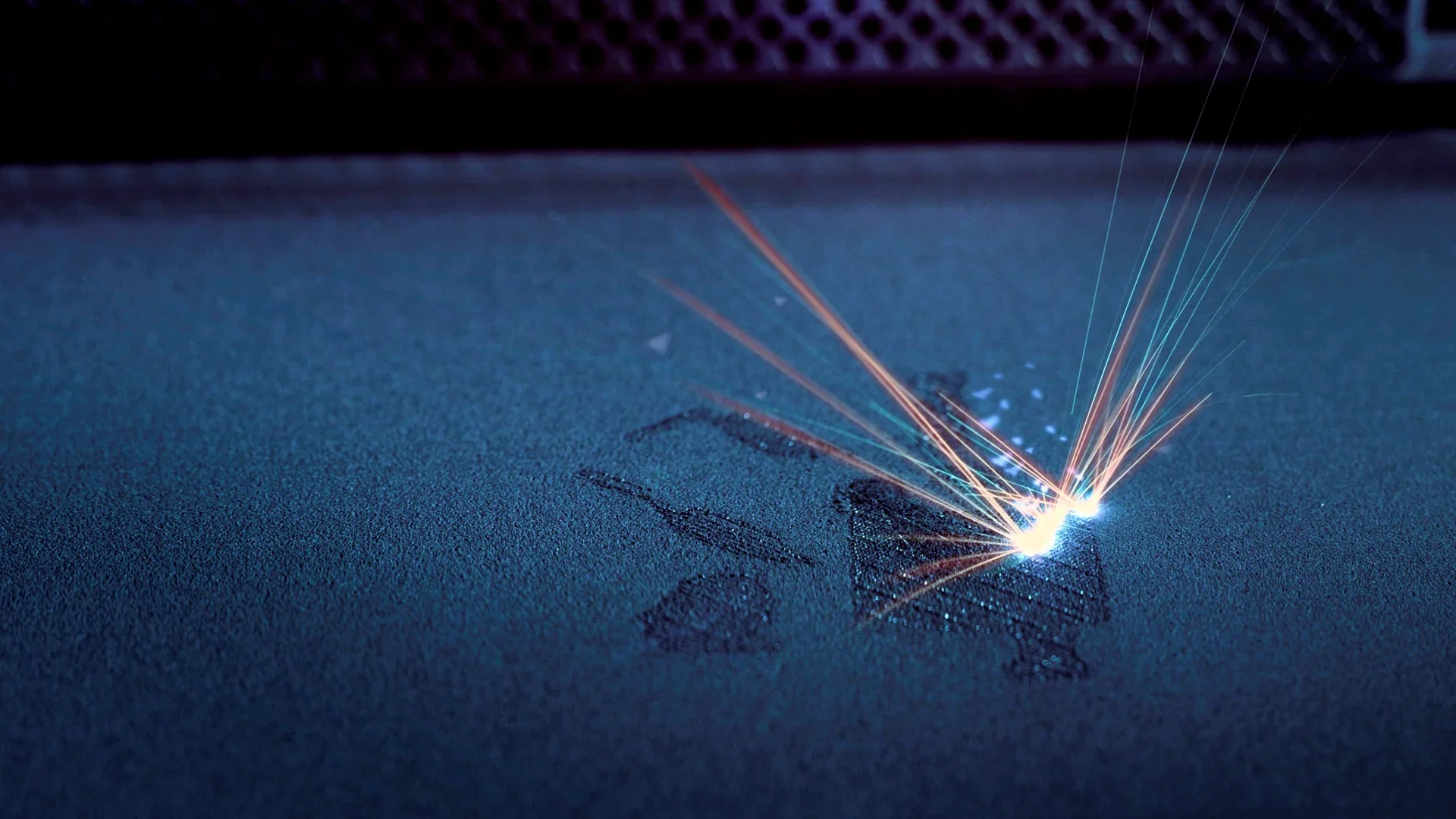

Metal Laser Sintering Working material for 3D printing process is fine powder metal. DMLS technology does not melt metal powder, so less energy is required. Metal Laser Sintering heats the particles sufficiently so that their surfaces fuse together.

DMLS technology follows the basic manufacturing process that is the same for most 3D printing technologies: 3D modelling, slicing the model to get it ready for production, and manufacturing it layer by layer. After a 3D model is created, transferred to the appropriate software and sliced, the data required for the printer to produce the part is transferred to the printer and the physical process begins. The DMLS 3D printer chamber is filled with the desired metal powder. In DMLS Technology, parts are produced by solidifying the powdered metal material laid in a thin layer on the production table with laser power under high temperature.

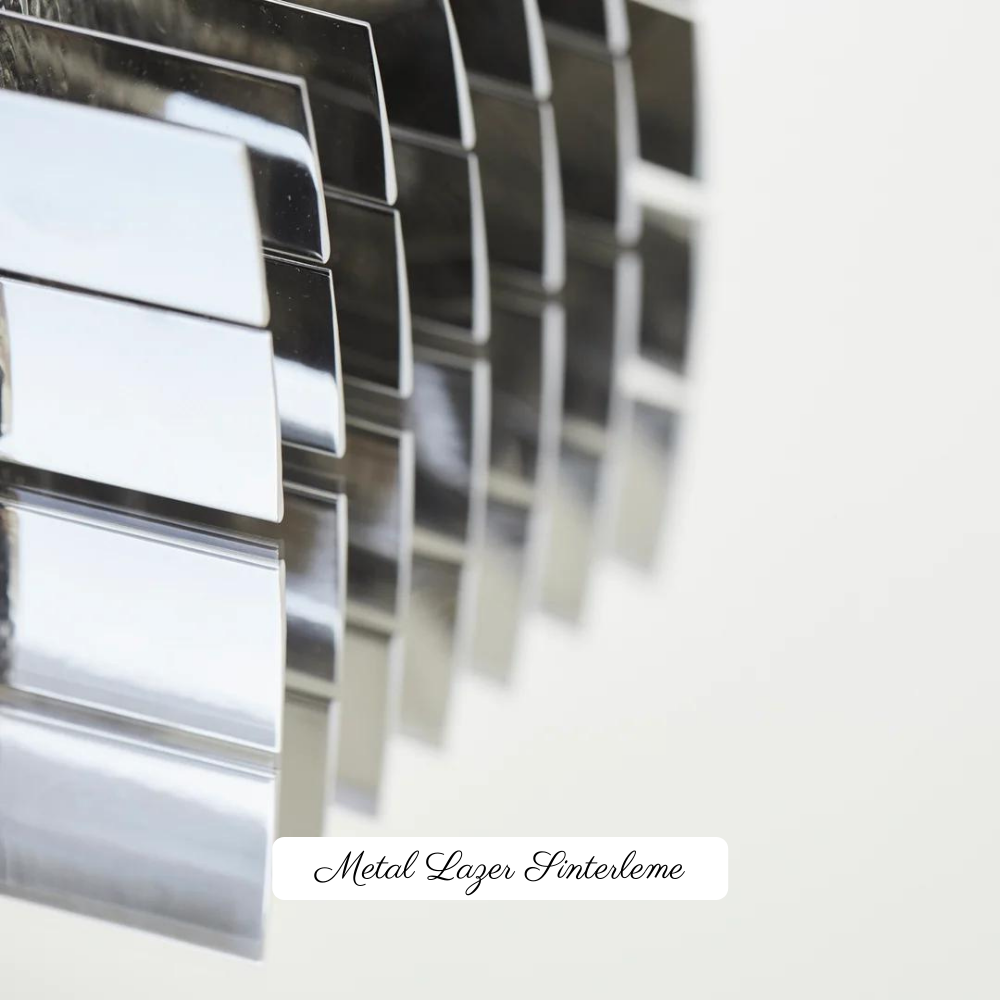

The part is left to cool. DMLS parts can be machined like metal parts produced by conventional metalworking for further processing. This may include machining, heat treatment or surface finishing.

Metal Laser Sintering Applications

and much more…

DMLS

Direct Metal Laser Sintering

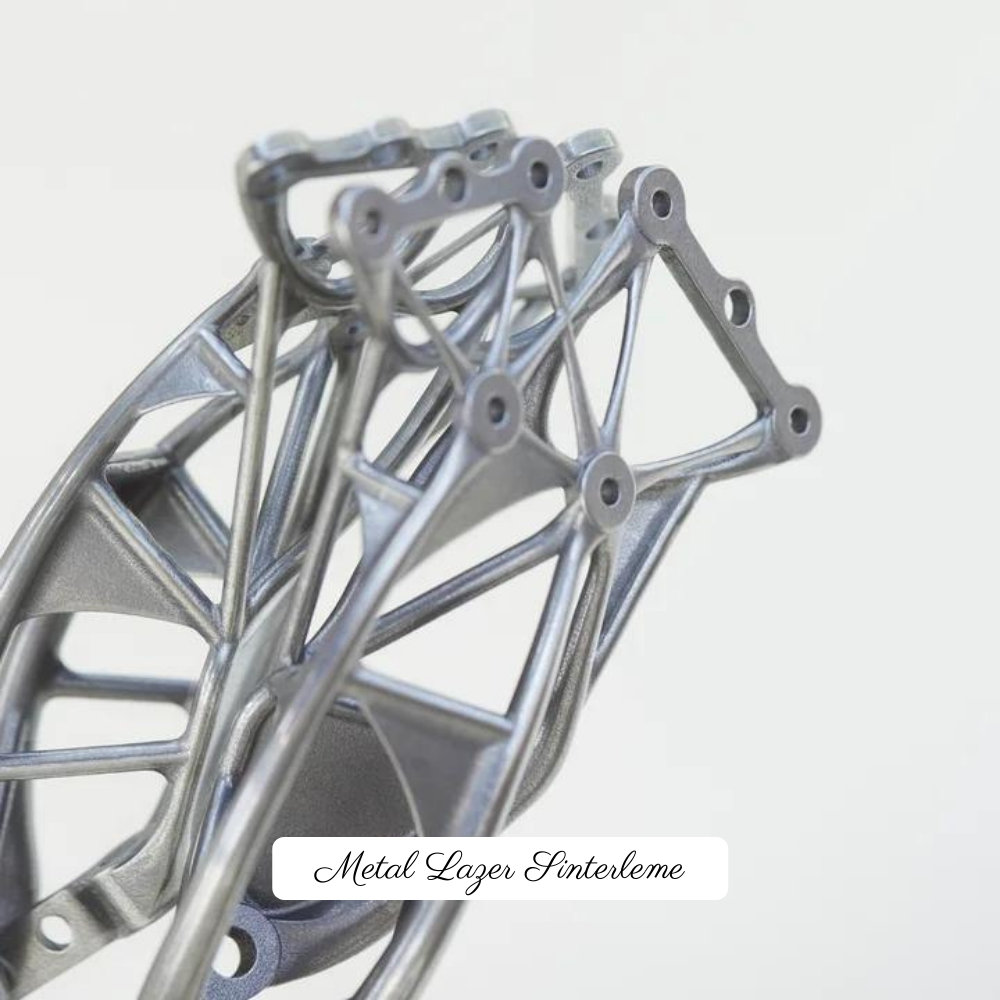

It can produce metal parts directly with DMLS. It can be used in DMLS 3D printers with metal alloys or pure metals without affecting the properties of the material. Even powder blends (eg aluminum and nylon) can be successfully printed.

A wide variety of metal and metal alloy powders can be used in DMLS 3D printers, including steels, stainless steels, aluminum, titanium, nickel alloys, cobalt chromium and precious metals.

Direct Metal Laser Sintering (DMLS Technology)

The properties of a finished part can be compared to a part cast from the same material. Strong, functional metal parts are produced with DMLS technology. The final parts have good mechanical properties in all directions.

It is an environmentally friendly system with recyclable materials. Sintered metal powders can be reused.

Areas that benefit greatly from the use of DMLS are the medical, dental, medical, automotive and aerospace industries. Parts needed by these sectors; often requires the use of high-performance or exotic materials. DMLS can produce parts that cannot be produced with conventional metalworking technologies.