Vacuum CastingSilicone Molding

You can contact us if you want to meet your low-volume parts needs at a more affordable cost and much faster.

Silicone Molding (Vacuum Casting) Technology, as one of the rapid production methods, entered the manufacturing sector as an indispensable manufacturing method in the 1970s. Silicone molding is used for different purposes such as mass production with small volumes, prototype production and model copying. Since mold production is done very quickly, it is also used as a prototype production method for testing purposes. In Silicone Molding technology, polyurethane-based Engineering Resins are used that simulate real materials. The parts that can be produced by silicone molding; enclosures and covers, anatomical models, large panels, bumpers, exhibition models and product requirements, transparent parts, rubber materials, functional part needs, parts that you will use in mechanical, tightness and low pressure tests, field test samples, products required for market research, in field conditions Examples are parts that meet the needs of end-user technical parts, laboratory tests completed, certified, dielectric, flame retardant such as UL94, high heat resistance, food-compatible engineering resins, and less number of end-user parts needs.

Silicone molding is much more cost-effective than injection molding costs and it is possible to get products much faster. It is preferred in small productions as it gives a better surface output and mechanical properties compared to the parts produced with a 3D printer. It offers flexible material options that you can choose between PC or 35-95 Shore hardness, as well as ABS-PP-PC ABS-PA6 and glass fiber reinforced materials in resins poured into the mold. The R&D and P&D departments of the companies are able to make design revisions before the injection mold, as they have the opportunity to perform critical controls such as design verification, mechanical assembly control and field testing, thanks to the silicone mold production service they have received before investing in the injection mold of their projects for which they have completed the design. This allows them to save time and cost by avoiding bad scenarios such as mold revision processes that they would have to do after injection molding, and even re-making the mold.

What is Vacuum Casting?

Vacuum casting,

Silicone Molding is where the necessary analyzes and tests (non-flammability, impermeability, etc.) can be applied on the part, before proceeding to the production of prototypes that meet functional, technical and mechanical values, production of small parts or multi-unit production for model copying, or in other words, mass production. It is a fast manufacturing method made with original or close to the original, that is, equivalent materials. It is also possible to produce complex parts with complex and difficult geometries with silicone molding.

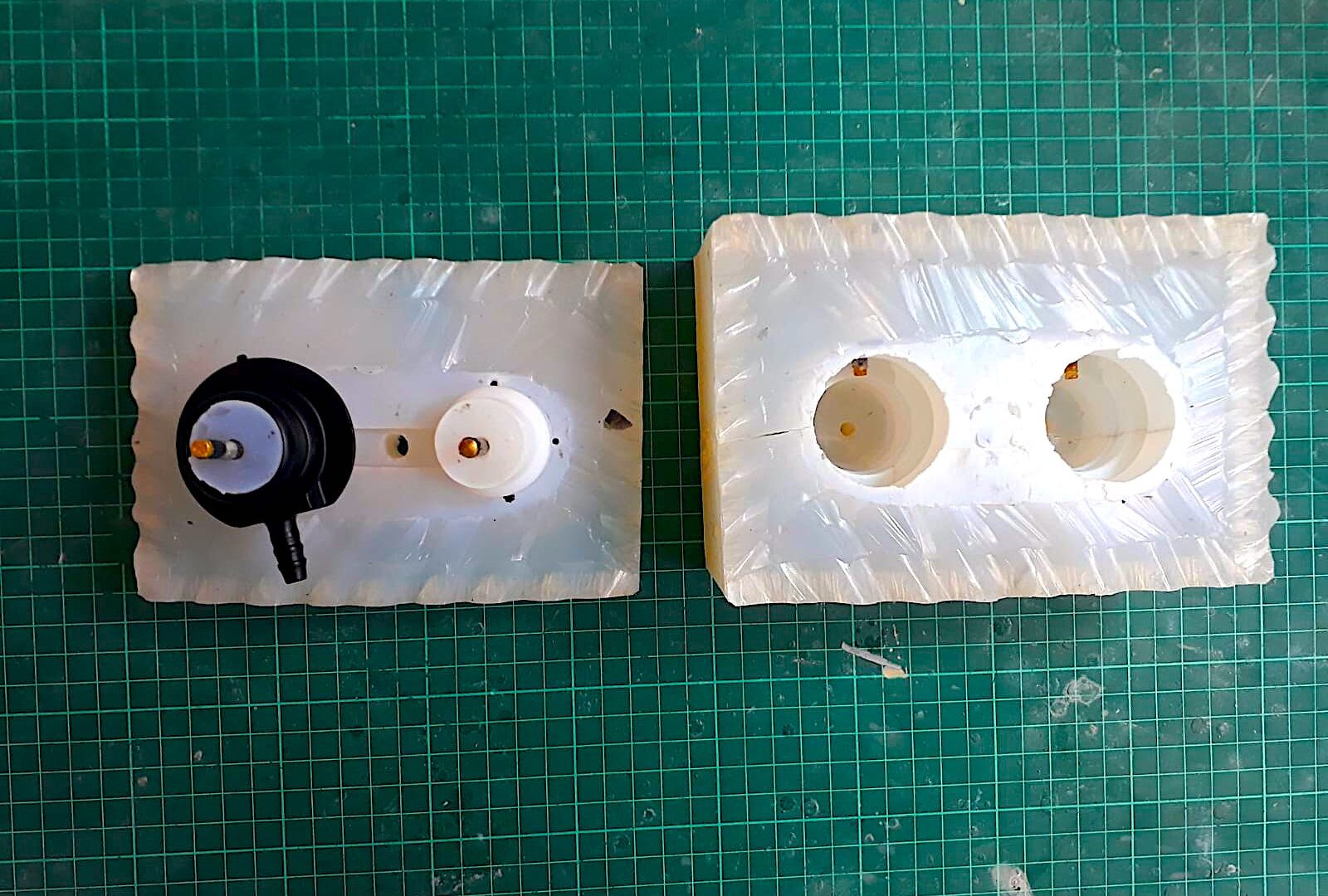

Silicone Mold Production

In order to produce with silicone molding, first a 3D model of the part to be produced is needed. The master model of the part, which is a 3D model, is first produced. It is possible to produce the master model by hand, CNC or 3D printer. In order for the master model to take its final form, the necessary surface treatments are done and now the master model is ready to be molded. Silicone is poured on this master model, which is produced in 3D, and the mold of the model is taken. The desired material is poured into the mold in a vacuum environment and the production of the part is started. Post-processing is applied to the parts produced with a silicone mold. That is, the pieces can be painted in the desired color, texture work or coating can be done. After quality control applications, the parts are ready for delivery.

The number of parts that can be taken from a silicone mold varies according to the geometry of the part. In parts with complex and difficult geometry, the silicone mold wears out early and the number of parts that can be taken from this mold is reduced. It is possible to say that we can get an average of 20-25 pieces from a mold in the silicone molding method. Considering both time and cost advantages, silicone molding will be the right choice for your small part production demands from 5 to 100 pieces.

Silicone Molding Service

Silicone Molding Service is a fast and cost-effective solution with a wide range of materials for low volume production!

We can use part handling materials with few technical and mechanical values that can be used with molding. It is in the production phase with molding in technical, mechanical, color and production design, which is produced with multi-manufacturing productions suitable for use in production.

Part Production with Vacuum Casting

Vacuum Casting is a technology preferred by different sectors and fields, especially end-user parts suitable for low-volume field conditions, automotive, defense industry, medical, white goods and small household appliances industries. Compared to the plastic injection molding method, parts can be produced faster and with more extended design conditions.

Silicone Mold Producing Companies

As Master Model, we maintain our leadership among companies that have been producing silicone molds for years. We are happy to be the first company that comes to mind in our sector with the production and application methods we have developed for silicone molding technology. We are proud of providing added value to our country’s R&D studies by producing parts with silicone molding technology for leading companies in white goods, automotive, defense industry, aviation, medical, health and similar sectors.