Reaction Injection MoldingRIM

We want to meet your small batch production needs with a wide range of engineering resins, time savings and low cost. Do not hesitate to contact us.

Developed by Bayer in 1969, reaction injection molding technology is a manufacturing method used to produce high-quality, primarily polyurethane thermoset plastic or thermoplastic-like parts. Reaction injection molding gives designers complete freedom, quickly, economically and geometrically, to design their imagination without compromising the structural integrity of the product.

With RIM (Reaction Injection Molding), an average of 50-500 parts can be taken from a mold, depending on the part geometries and structure. It is important to get the rim molding service, where you can meet your low-volume part production needs at a more affordable cost, from an expert and experienced team.

In general, Reaction Injection Molding has the advantages of being able to manufacture larger parts, shorter mold cycles, no need for mold solvent cleaning cycles, improved surface quality, and faster injection into the mold than standard low-pressure mechanical mixing systems.

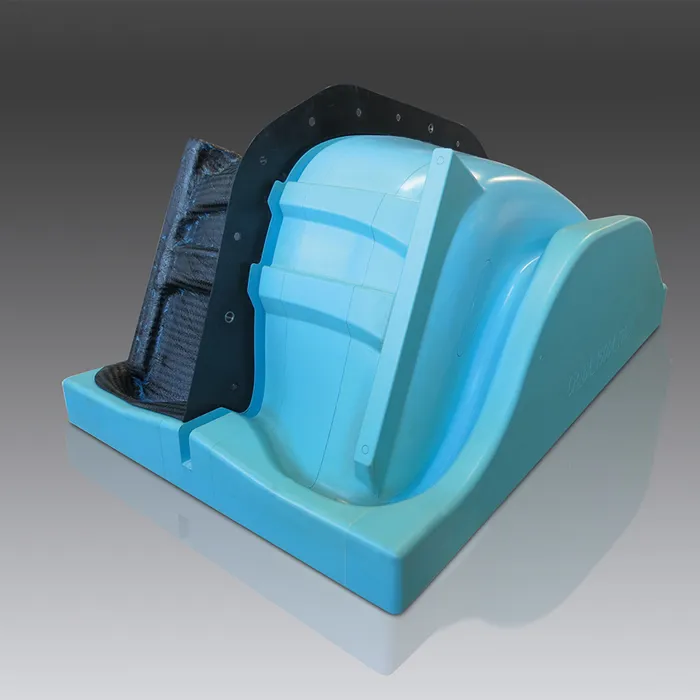

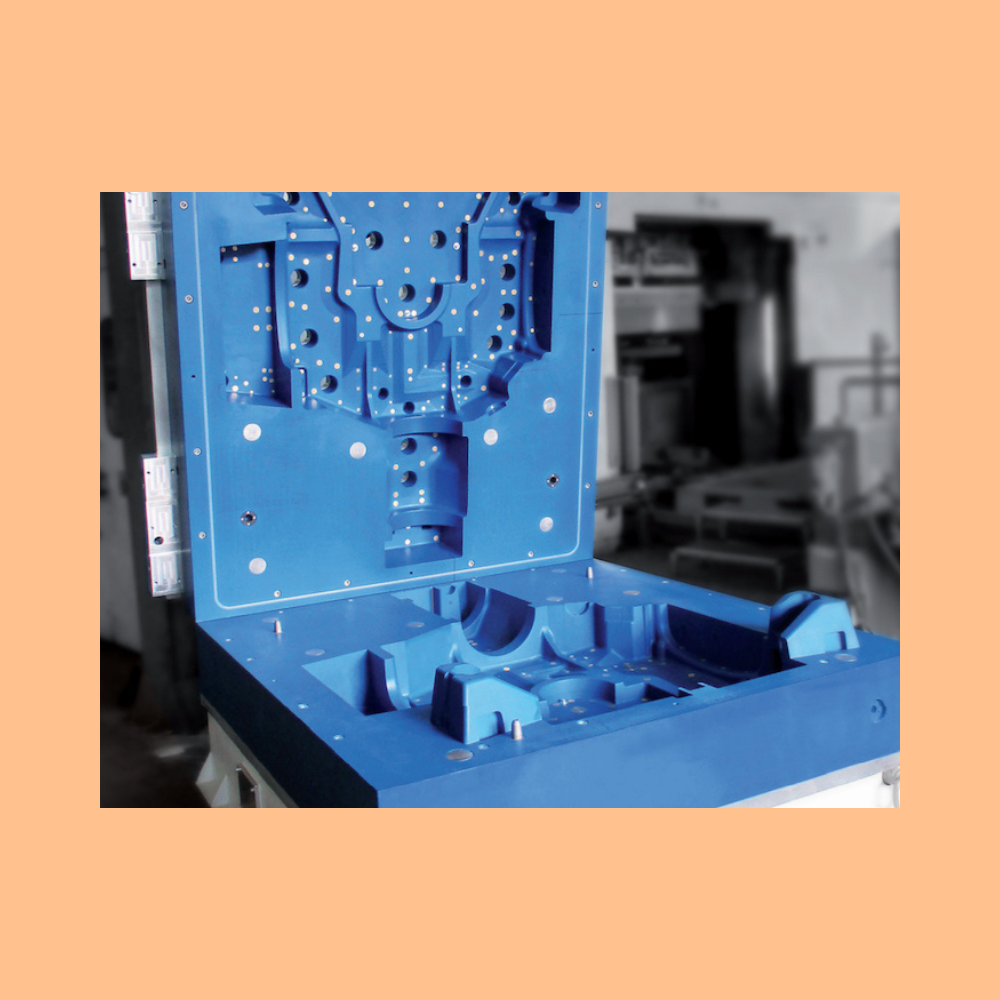

Reaction Injection Molding Application Examples

and much more…

What is Rim?

Rim (reaction injection moulding),

High performance engineering resins are used for low pressure RIM Technology. A manufacturing process in which two or more raw materials (isocyanate and polyol) come separately into a mixing head, where they are combined by low pressure impact mixing and then flow into a mold to form a molded part.

Reaction Injection Moulding

Reaction Injection Molding is a multi-step process that includes procedures different from standard injection molding. To begin, two or more types of molten plastics, such as polyisocyanate and a resin compound, are poured into separate reactant tanks equipped with temperature and feed control mechanisms. The liquids are then released into the respective supply lines and directed into a metering chamber that regulates the pressure and circulates the plastic in a mixing head.

The mixing head typically applies pressures between 1,500 and 3,000 psi to mix plastics by impact. After the reactants are mixed, they are injected into the mold at high speed. The mixing head stops releasing reactant when the mold is full. An exothermic chemical reaction occurs within the mold and results in plastic polymerization. After the polymer has solidified or “cured”, it is removed from the mold in component form.

RIM machines perform this process using low temperatures. Besides the heat required to form the molten plastic, reaction injection molding is a relatively cold process. RIM generates chemical energy caused by polymerization reactions rather than thermal energy. The dies used are typically made of steel, aluminum or nickel and are compressed in a light weight press. The cure time of the polymer is usually under one minute, resulting in fast turnover and fast production cycles for medium volume operations.

Part Production with Rim Molding

Reaction Injection Molding is a fast and cost-effective solution for low volume production!

With the Rim molding method, which is the method frequently preferred by the manufacturers of end-user products, defense industry manufacturers and special vehicle manufacturers in particular, parts can be produced faster and the design conditions are much more expanded than the plastic injection molding method.